High Temperature Resistant Coatings & Paints

With some of the most skilled and innovative chemists in the business, Crossroads Coatings is always on the cutting edge of formulation development and manufacture of quality High Temperature Coatings. For each and every customer, we create custom coatings for heat resistance in applications across numerous industries. Most notably, our heat protection coatings are used on woodstoves, fireplaces, outdoor fire pits, BBQ grills, smokers, and gas logs. In aerospace, Crossroad's coatings are used in applications such as launch and exhaust systems.

WE ARE A HEAT PROTECTION COATINGS FORMULATOR

We develop and formulate the highest quality High Temperature Coatings for applications across all industries. Request A Quote for your supply of custom-created coatings today!

About Our Heat Resistant Coatings

Our high temperature coatings are formulated with a multitude of silicone resins, resin modifiers, and other resin combinations. Formulations can be developed for temperatures ranging from 600°F to 2200°F, depending on the substrate. Additionally, we can meet most VOC requirements and develop coatings free of HAPs and TAPs. Crossroads is on the cutting edge of innovation, as we have developed the very first and only true 1200°F water-based, air-dry, heat-resistant coating, Aquatemp.

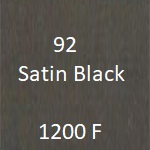

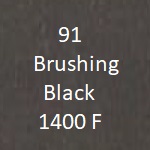

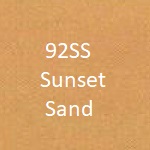

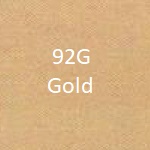

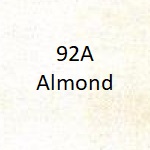

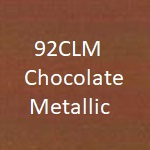

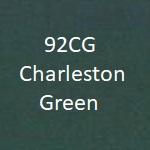

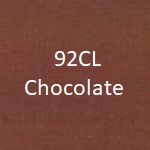

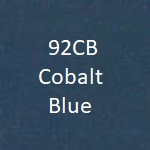

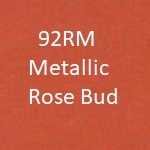

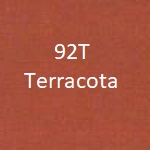

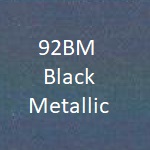

Our Corrosion Resistant Coating & Paint Colors

The basic colors for our High Temperature Resistant coatings are black, metallic black, and the range of colors below: or » View our High Temperature Coating Color Chart

|  |  | |

|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

What Is High Temperature Corrosion?

Metals in environments with exposure to elevated temps and caustic substances are at risk for high temperature corrosion. The metal can react with the oxygen in the air, which forms metal oxides. At increased temperatures, the metal’s atoms move around more, making it easier for corrosive agents like moisture and acidic gases to penetrate and weaken the metal.

Damage from high temperature corrosion shows up as pitting, cracking, or overall weakening. This deterioration can seriously impact critical applications, causing leaks, equipment failures, and dangerous accidents. In addition, corrosion can be expensive and disruptive due to frequent repairs and replacements.

How Do High Temperature Corrosion Resistant Coatings Work?

Our heat resistant coatings have the following features that preserve metal surfaces:

- Barrier Protection: Physically block moisture, oxygen, and corrosive agents

- Thermal Stability: Withstand extreme thermal levels without breaking down

- Chemical Resistance: Also resist various aggressive substances

- Adhesion: Bond strongly to substrates and remains intact during thermal cycling

Crossroads offers heat resistant paints that are more cost-effective and easier to apply, touch up, or repaint. However, high temperature corrosion resistant coatings provide better heat resistance, bond more strongly, and last longer than high temperature paints.

High Temperature Refractory Coatings

High temperature refractory coatings are specialized materials used in industrial applications that generate extreme heat, such as furnaces, kilns, and boilers. Types typically include:

- Ceramic coatings

- Silica-based coatings

- Magnesia-based coatings

- Zirconia-based coatings

Refractory coatings can withstand ultra-high temperatures that exceed 1,500°F and remain effective up to 2,200°F.

Heat Resistant Coatings for Metal Applications

Several types of heat resistant coatings are especially well-suited for metal applications:

- Ceramic-Based: Excellent for extreme heat levels

- Silicone Resin: Preferred for high heat cycling uses

- Epoxy Phenolic: Chosen for superior chemical resistance

- Polyamide: Renowned for thermal stability

- Zinc Silicate: Dual protection from heat and corrosion

Common in aerospace applications, thermal barrier coatings consisting of a top ceramic layer and a bond coat are also useful for extreme thermal conditions.

Corrosion-Resistant Applications

Applications that need additional safeguarding from other types of corrosion, as well as heat, include the following:

- Aerospace components operate in environments that include moisture and corrosive chemicals

- Automotive exhaust systems face exposure to corrosive exhaust gases

- Power generation equipment encounters corrosive elements such as steam and chemicals

- Oil and gas pipelines and drilling components need protection from organic acids and hydrogen sulfide

- Industrial furnaces and ovens frequently come into contact with acidic gases and molten salts

Furthermore, saltwater can be especially corrosive to components in the marine industry, especially in high heat situations.

Heat Protective Coatings for Hearth & BBQ Industry

Since our founding in 1952, Crossroads Coatings has taken pride in evolving our coating product development, and a large part of this has come from our close work with customers in the Hearth and BBQ industry. No matter the size, material, or shape of the hearth or BBQ, Crossroads has formulated a coating for it, and will be happy to custom-create new coatings for new projects. Our engineers take pride in formulating coatings that save you time and money in the long run and extend the lifetime of your equipment. Products such as our high-temperature coatings and our environmentally friendly coatings, among many others, have proven to work great with hearths, BBQs, and related fixtures and equipment, such as smokers and outdoor fire pits.

Industries Using Our High Temp Coatings

We create custom coatings for high-heat resistance applications across numerous industries:

- OEM

- Industrial Manufacturing

- Aerospace

- Automotive

- Construction

- Niche Markets

- Industrial Maintenance

- Military

- Hearth & BBQ

Customized High Temperature Coatings From Crossroads

All of our high temperature coatings are formulated for quality and functionality. They can be tailored to meet most standards pertaining to health and the environment. Request a quote today, and we will be glad to help you get the right start on your coating project by supplying a coating perfectly designed to your specifications.

Click here to Request a Quote Or call us at 1.833.724.6816